Electrical system health

How many of you start an electrical diagnosis by checking the battery state

of charge or charging system voltage? I’m not saying you don’t, however, in my travels, I

have been to many different shops and have seen this overlooked a lot.

Good source voltage is extremely important, more so in modern vehicles.

Solenoids, actuators, sensors, switches, and computer modules are needed to operate a modern

automatic transmission, which is a substantial demand on the electrical system. If

the source voltage is low or unstable those components will not operate correctly and cause

any number of driveability complaints or possibly lead to unit failure. Any diagnostic

results taken with poor supply voltage could lead to misdiagnosis. We must verify the

integrity of the system before proceeding. Of course, Moveras’ focus is automatic

transmissions, but electrical principles apply just the same in the entire vehicle.

Battery state of charge

Safety is most important:

YOU MUST KNOW WHAT YOU ARE WORKING ON AND HOW IT WORKS. If you’re

working on an EV or Hybrid vehicle with High voltage systems there are

several safety measures that must be taken before touching the electrical system, refer

to the factory service procedure on making the high voltage system safe prior to any

work.

*Note, If you’re

working on a vehicle with an auxiliary battery or duel battery

system you need to isolate the batteries from each other during this test

or one may mask an issue with the other.

Start by measuring the battery voltage at the battery terminals with a

high impedance (10 megaohm) digital volt-ohm multimeter

(DVOM). A standard 12-volt lead-acid battery is made up of 6 cells that, in good

condition, measure 2.1 volts each, so with that, your reading should be 12.6 volts. There

are other factors like surface charge and system draw that could affect this reading up or

down. Surface charge may be present if the vehicle was recently running, and the battery was

being charged. If that is the case turn on a few loads such as the headlights and windshield

wipers for a couple of minutes, then shut off the items you turned on and the voltage should

stabilize close to 12.6 volts.

If you have low voltage and notice it dropping consistently you may have a

draw on the system, however, vehicles today have a lot of computers in them, and they draw

on the battery when they are “awake”. In order to test for a draw you will need to find the

manufacturer's procedure to put them all in “sleep mode” before testing for a draw. If you

notice a draw you will want to consult the factory service manual and look up what the

acceptable amount of draw is. Any draw will eventually drain the battery, so it is good to

use a battery maintainer/charger for long-term vehicle storage.

Battery load test

This should be performed next. If you have a battery load tester that is

the correct way to assess the battery, any other tests are

subjective. A process that has worked for me in the past, is to turn on every

electrical load you can find, like, the HVAC fan on high, rear window defrost, wipers on

high, headlights on high beam, fog lights, hazard lights, interior lights, etc. with your

meter connected, and the vehicle ignition in the run position while the engine is

off. If the voltage drops below 10.5v during this test the battery

should be replaced.

*If the vehicle has an electric cooling fan you can

turn it on with the bi-directional control

feature in the scan tool.

The fan will easily draw over 20 or 30 amps. If

bi-directional control is not available simply jump the fan relay.

Another way to load the battery is to use the vehicle's starter. Start by

disabling your fuel or spark to prevent the vehicle from starting. With your meter connected

to the battery terminals and visible from inside the vehicle, crank the vehicle for no more

than 15 seconds. Because this test will put more load on the battery than the test above,

you should not see the voltage drop below 10 volts during cranking.

In either of these tests, the recovery time should be fairly quick, and the

battery should return to around 12.6 volts.

Charging voltage

With the multimeter still connected, reverse what was done to disable the

vehicle from starting and start the engine. With the engine running at idle, you should see

13.5 to 14.5 volts at the battery terminals. You must load test the alternator too. You want

to turn on as many loads as possible and see if your charging voltage remains at 13.5-14.5,

if so, your system is working correctly.

*Important- the specifications listed here are general and not specific

to any make, model, engine size, battery type, or charging system. It is in your best

interest to look up your specific application, again know

what you’re working on and how it works.

Voltage drop testing

A tried and true method of testing electrical circuits is voltage drop, and

it is the preferred method for several auto manufacturers. Unlike resistance testing which

must be done only when power is removed from the circuit, Voltage drop tests must be

conducted on a live circuit under load. This is a major advantage because resistance testing

will not prove the circuit is capable of carrying current (amperage), however voltage drop

will. Once you have perfected your method of voltage drop testing it will become your

preferred method too.

What is voltage drop testing? It is a measurement of the voltage consumed

by the resistance between any two points you’re measuring. If you remember back to basic

electrical class, you need voltage to move amperage through a resistance. This form of

testing shows where the voltage is being consumed in a circuit. In an ideal world, voltage

would only be consumed by the load in the circuit, meaning that all the energy went to the

component the circuit is powering. We don’t live in an ideal world and superconductors are

not used in automotive, so we have resistance points other than the load in the circuit.

As a general rule, there is an allowance of .1 volt per connection in a

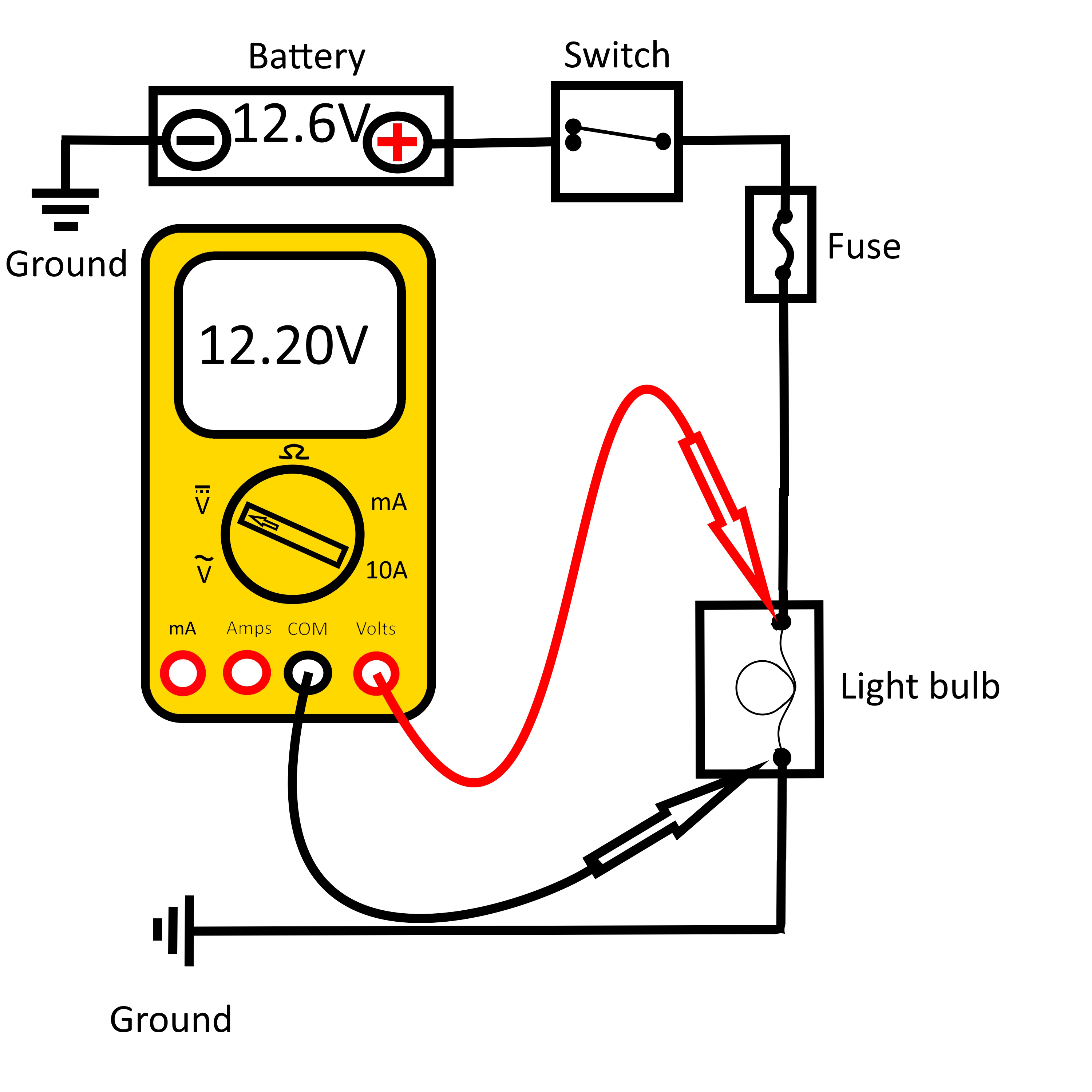

circuit, this drop is due to the resistance of each connection. In Fig. 1 the battery is at

12.6 volts, because there are 9 connections, and each is allowed .1V per connection you may

have a drop of up to .9 volts (900mv) across the entire circuit. The DVOM is reading 12.2

which means the light bulb consumed 12.2 volts of the available 12.6 which means the circuit

only consumed???? Yes, .4 volts (400mv), which is less than the allowance.

Fig. 1

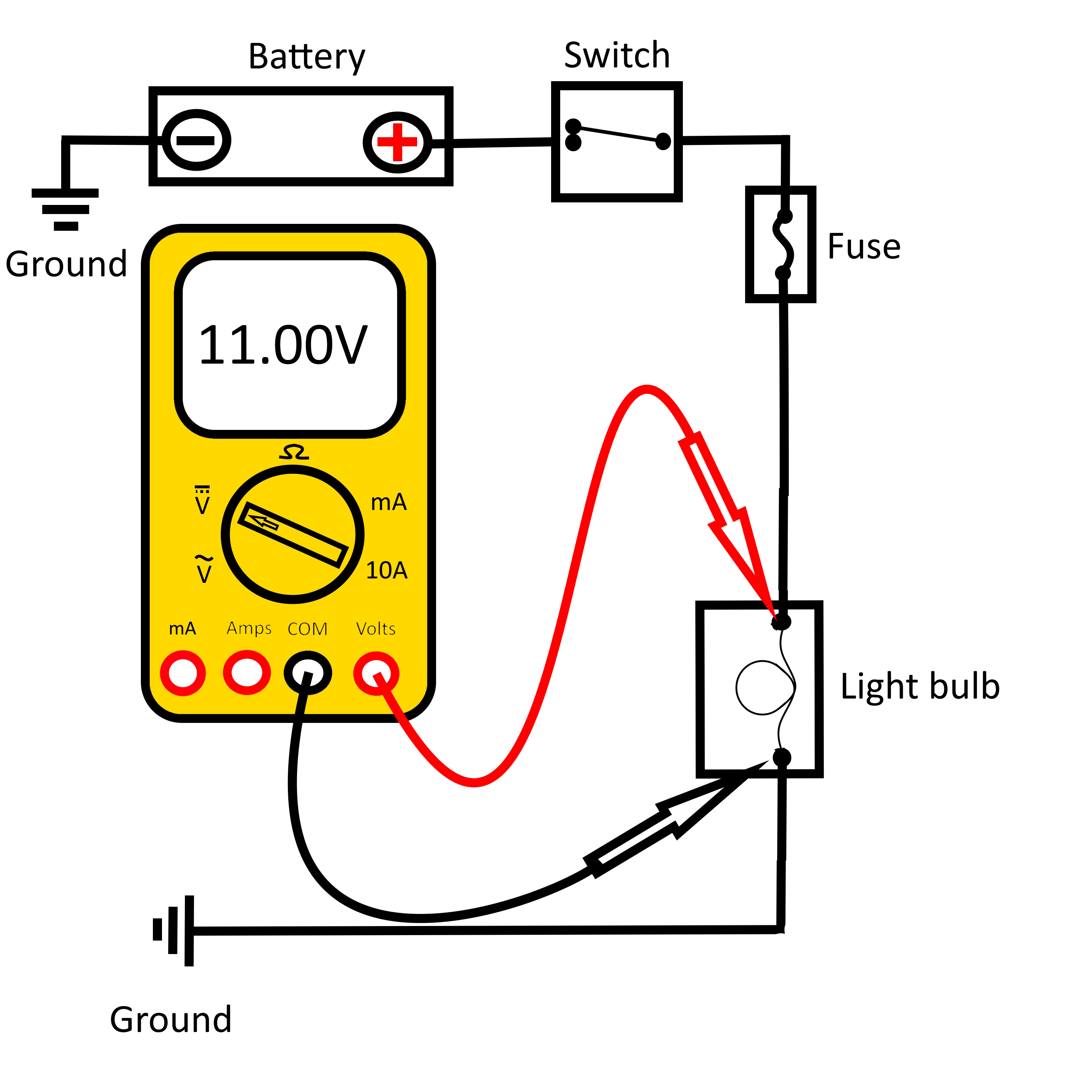

In Fig.2 the circuit consumed more than 1 volt because the light bulb only

was able to consume 11.0 volts, which means we need to find the other 1.6 volts. Further

testing would be needed until you find the point that is consuming more than allowed.

Fig. 2

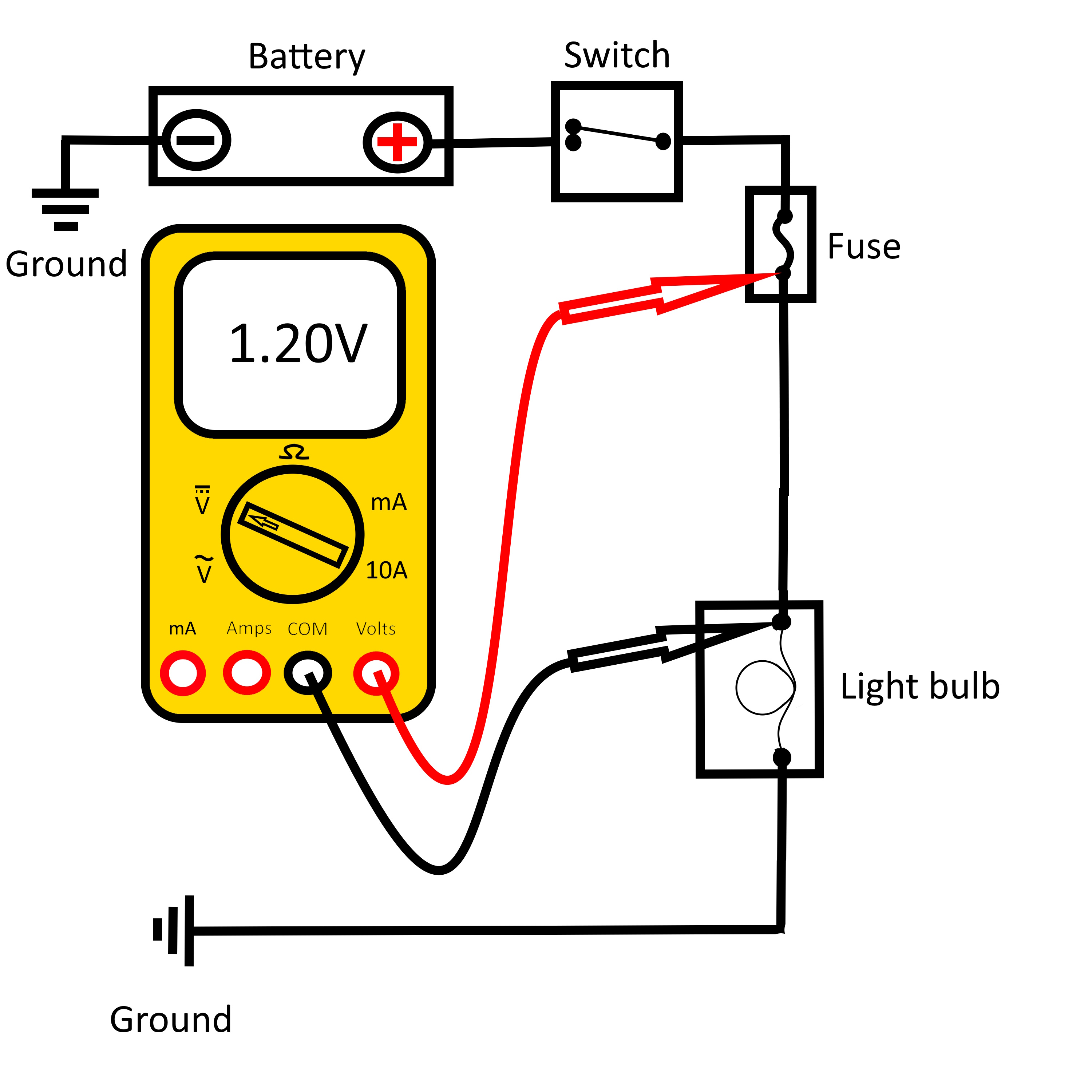

When we tested between the fuse and the light bulb, we found a 1.2 volt

drop as seen in Fig.3.

Fig. 3

In this case, a good visual inspection of the wiring between these two

points should be done. You may find damage to the wire, corrosion, loose connections etc.

Don’t forget to check your grounds!!! The same rules apply to the negative

side of the circuit as the positive. Check the battery negative to the engine block and the

body to ensure you are not consuming voltage on the ground side of the circuit. It helps to

look at an electrical circuit as a loop and any part of the loop affects the entire circuit.

*Something that may be overlooked is pin tension. Male and Female

connections must be tight to make good contact! There are tools that will measure

pin tension, or you may make your

own. If you will be doing

this type of diagnostic work, it is

strongly recommended to have something to check this.

Case study

Voltage drop testing can be used on any Direct Current system, while

diagnosing a failed starter on a tractor, it was determined that the battery terminals were

faulty.

As you can see on the left, the cable going into the terminal looked good,

nothing indicated what we found inside. When we peeled back the wire covering it was evident

that we found a problem. There was a voltage drop of 4.5 volts between the terminal and the

connection point at the starter. This showed us where to look for the problem.

*There is another method of testing that has

become very fast and helpful, and that is thermal

imaging. With a thermal imager, you will see the heat that is a byproduct of high

resistance.

How does bad battery terminals lead to a faulty starter you ask? Remember a

healthy battery has 12.6 volts of potential. If 4.5 volts are consumed before it reaches the

starter, then only 8.1 volts are getting to the starter. The amperage at this point must go

up in the circuit to overcome the resistance (Ohms law), this causes components to overheat

and fail, which is exactly what happened to the starter. This example will apply to all

electrical components in the vehicle, so, you can see how important it is to have good

connections, especially at the battery terminals.

Summary

Keeping with our theme of back to basics we need to remember to check the

easy stuff that can cause us the biggest headaches. It doesn’t get much easier than checking

the source voltage and battery terminal connections. With the testing processes outlined

here, we hope that this will speed up the process with the most accurate results.